Time for a Canopy Sprayer Tune-Up

Many problems associated with pesticide application can be prevented if sprayers are calibrated and adjusted correctly. Poorly calibrated sprayers can lead to less than ideal application. Over- application causes residue concerns and may result in crop loss due to phytotoxicity; it is also responsible for economic loss, because more spray is applied than is needed. Under-application or inconsistent application, on the other hand, have an economic cost due to crop loss from poor disease- and insect-control, as well as lower crop quality.

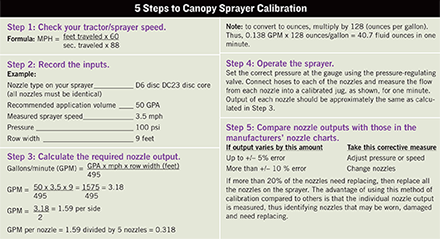

Calibration of canopy sprayers

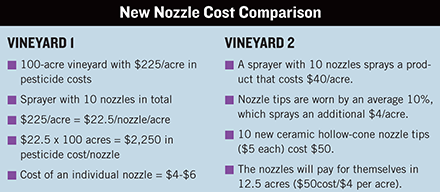

Replacing worn-out nozzles and matching the correct nozzles to the type of application is a fairly inexpensive practice that reduces over-application, can reduce drift and also saves money. Application rates will be more constant and easier to adjust with a correctly calibrated sprayer.

Nozzles are inexpensive items within the scheme of application technology (see table below). The examples show that the cost of purchasing new nozzles compared to the cost of pesticides passing through the nozzles is extremely low. A growing number of growers replace all their nozzles on an annual basis rather than spend time and labor costs calibrating sprayers.

Watch a video about selecting and changing nozzles: Calibration of Airblast Sprayers for Vineyards. Part 1: Selecting and Changing Nozzles.

Travel speed is a critical factor in maintaining accurate application rates, and it influences spray deposition within the canopy. All studies to date show that the higher the travel speed, the greater the variability in spray deposit.

Unfortunately, most tractors rarely display an accurate forward speed, so the grower has to determine the forward speed based upon the engine speed necessary to provide 540 PTO speed. The best way to measure travel speed is to pull a sprayer with the tank half-filled with water on the same type of terrain that the sprayer will be operated on. Never use a hard road surface.

Set up a test course at least 100 feet long. Measure the course with a tape measure, and do not pace the distance. The longer the course, the smaller the margin of error will be. Run the course in both directions.

Use an accurate stopwatch to check the time required to travel the course in each direction. Average the two runs and use the formula in Step 1 below to calculate the speed:

Make a note of the tractor gear and engine revs to provide a PTO speed of 540 rpm.

Forward speed may also be measured using a simple hand-held GPS device. The type used by hikers and hunters costs less than $100 from sporting goods shops. This device provides a fast and accurate method of measuring forward speed and is transferrable between farm vehicles. Many electronic devices found on modern sprayers, such as automatic flow controllers, also incorporate forward speed measurement systems.

Canopy sprayer calibration

Before calibrating, test the sprayer with water to ensure there are no leaks. When calibrating, run the tractor engine at the correct speed to provide a PTO speed of 540 rpm. Ensure the tractor brake is applied, and be very careful if working near the PTO shaft. Always use clean water when calibrating a sprayer.

Watch a video about this method of calibration: Calibration of Airblast Sprayers for Vineyards. Part 2 Measuring Liquid Flow.

Monitoring spray deposition

Once the canopy sprayer is properly calibrated, you can start positioning the nozzles to spray the target area effectively. Growers can assess how well their crop sprayer deposits the spray onto the target by using a number of different methods. Simple techniques allow the operator to monitor deposition and detect drift—cards and tracer dyes allow the grower to see the effect of changes in forward speed, application volume, airflow and speed, as well as different nozzle types and other machine adjustments.

Water-sensitive cards and strips, manufactured by Syngenta, are available in 3-inch x 1-inch (75mm x 25mm) lengths. These little yellow cards turn blue whenever water droplets touch them. They can easily be attached to leaves with paper clips or staples, as long as the canopy is dry and the user wears rubber gloves. They are quite expensive. They show where water droplets have hit the upper or lower leaf surfaces and how close the water deposits are to the grape cluster.

High quality photographic paper cut into 2-inch x 1-inch (50mm x 25mm) strips attached to the leaves and used in conjunction with a readily available kitchen food dye provide a very inexpensive alternative to water-sensitive cards. Quality photographic paper for printing digital photos can be purchased at office supply shops. Food coloring dye can be poured into a sprayer tank containing a small amount of clean water (check dilution rates). The spray droplets leave their mark as they hit the photo paper.

Surround, an organic insecticide based upon Kaolin clay, is highly visible on most green vine leaves and grapes. It should be premixed in a bucket before going into the spray tank, or it will block the filters. Keep tank agitation working at all times to avoid problems. The spray will dry rapidly on a summer day, and in approximately 10 minutes you will see all the droplets on the leaves and grapes, looking like snow.

Fluorescent tracers and an ultraviolet (black-light) lamp provide an excellent means of seeing where the droplets have landed. A number of products can be used such as Pyranine (Keystone Chemicals, Chicago). Tracer is mixed in the spray tank and applied to the canopy during twilight. Growers will have to wait until dark to see the droplets in the canopy or remove leaves into a darkened area. Inexpensive ultraviolet black lights are available online. (See photo of fluorescent tracer under black light on page 43.) The photographs show that as application rate increases, the droplets coalesce and run down to the leaf margin. Interestingly, as more liquid is applied, less spray actually remains on the leaf due to surface runoff.

The batten method is a simple technique that uses a 14 feet (4.3 meters), 2 x 1 inch (50mm x 25 mm) wooden batten with a paper tape stapled to the leading edge. Paper tape, as used for office calculators or cash registers, is ideal. Staple the paper roll at every 12 inches, (300mm) to avoid the high airspeed from blowing it off.

The batten is placed vertically in the canopy and attached to the top wire of the canopy trellis. If you have a second pole, place it in the target row on the opposite side of the sprayer. If you have plenty of poles, you can place them in the adjacent rows to see the spray drift.

The sprayer has food coloring added to clean water in the tank and drives past the batten. The operator can clearly see where the spray droplets have gone. The nozzles can be adjusted (turned upwards, downwards or off to adjust the spray cloud). Attach a new piece of paper tape and drive past the batten again to see how the droplets are in the target zone; hopefully they are not drifting as far up into the sky. This is a simple yet effective method.

The patternator resembles a mast with catching screens that intercept and catch the spray plume. The spray cloud hits the screens and runs down into a collecting trough, then down plastic pipes into graduated collecting vessels. The results obtained from a patternator show which areas of the canopy receive either too much or too little spray. The patternator is superior to the wooden batten method detailed above, because the effect of changes to individual nozzles can be observed. In our trials of many air-assisted sprayers, a number of the nozzles are turned off to reduce drift while still maintaining the desired deposition.

Orientation of the nozzles can also be adjusted on many sprayers to reduce drift and improve deposition. For example, nozzles set in the “typical growers” pattern (i.e. pointing radially outwards), resulted in a large quantity of liquid being blown above the target row. The quantity overshooting the target varies according to canopy height, density and size/speed of the fan. There is a great imbalance of distribution between the left and right-hand sides of the sprayer due to the airflow characteristics and nozzle orientation. When nozzle orientation is adjusted for differences in fan rotation, we have found a 20% improvement in spray deposition within grapevines.

To assist in adjusting the nozzles, a vertical patternator can be used. The Cornell University patternator comprises nine 14-inch x 48-inch wide fly screens connected via hooks to two 14-foot high, 4-inch x 2-inch wooden boards. A small gutter is attached at an angle to the bottom edge of each screen. The gutter slopes to one end, where a plastic hose connects it to a box containing graduated measuring cylinders. The sprayer tank is filled with clean water, the patternator is placed at the end of a row, and the sprayer is operated but remains stationary As the spray cloud hits the fly screen, air passes through and liquid runs down the front of the screen, into the gutter and then, via the plastic hose, into the collecting cylinders. Plans for the construction of the Cornell patternator are available on the online at: nysaes.cornell.edu/ent/faculty/landers/pestapp/patternator.htm.

Andrew Landers holds a faculty position at Cornell University where his research, extension and teaching position is based upon application technology to the fruit industry. He conducts an international program and gives more than 45 conference presentations each year across the world. He is author of the forthcoming book Effective Vineyard Spraying obtainable from: effectivespraying.com. To comment on this article, e-mail edit@winesandvines.com.

|

|

PRINTER-FRIENDLY VERSION » |

|

|

E-MAIL THIS ARTICLE » |